Antenna

LLAMA radiotelescope has the same design of the antennas manufactured by the German company VERTEX for the ALMA (Atacama Large Millimeter / submillimeter Array): 12 m of diameter and focus Cassegrain. In addition, the antenna will have two cabins in the Nasmyth focus, similar to the APEX (Atacama Pathfinder Experiment). At the time of acceptance, the surface of the antenna should have an accuracy of rms of 25m and should be improved up to 15m. The pointing accuracy should be of at least 2 arcseconds.

The antenna has already been built and sent from Europe to the site in Puna de Atacama, Argentina's Province of Salta (longitude 66o 28' 29.4''and latitude -24o 11' 31.4''), at about 4800 m altitude. At this moment, the construction of the foundation of the radio telescope is being made feasible. Then the antenna assembly will start, which should be done in six months.

APEX radio telescope, installed in northern Chile. The LLAMA antenna was produced by the same company, has the same dimensions and the two Nasmyth cabins.

Containers with LLAMA's antenna dismantled, already at the final site, at 4800m altitude.

Assembly, Integration and Verification (AIV)

For the AIV phase, two subsystems will be needed: the optical telescope and the holography. The first one is installed parallel to the antenna axis, in a specially designed hole in the surface of the antenna, and will be used to measure the position of bright stars. As there are few punctual and intense astronomical sources in the LLAMA working frequencies, the use of the optical telescope is a useful resource not only for the evaluation of the quality of the pointing, but also to begin the elaboration of the antenna pointing model. The final model for operations is determined through observations of radio sources and must be periodically checked and improved.

The hole in APEX’s surface is used for the installation of a system that includes an optical refractor telescope to check the pointing. LLAMA will use the same resource.

In this turn, holography is the technique used to measure the refine the quality of the surface of the antenna. A tower will be installed about 300 meters from the antenna with a 104 GHz transmitter at its top. In the secondary focus of the antenna will be installed a receiver with two horns, one pointing towards the direction of the transmitter and one towards the surface. Using the difference between the signal received by the first and second horns, it is possible to construct a map of the surface indicating the adjustments to be made in the panels to improve the quality. Holography and optical observations are the first steps to verify the antenna performance after its assembly.

First receivers

At the beginning of LLAMA operations, two ALMA receivers will be available in bands 5 (157 - 212 GHz) and 9 (602 - 720 GHz). The receivers, cooled to the temperature of the liquid He, will be placed in one of the Nasmyth foci (the so-called cabin B) and inside in a cryostat that holds up to three receivers. The cryostat was manufactured by the National Observatory of Japan (NAOJ), while the receivers are being developed in collaboration with the Universities of Leiden, Radboud and the NOVA institute, all of them in the Netherlands.

LLAMA receivers in band 5 (left) and band 9 (right). The second one was produced by NOVA (The Netherlands), while the first one was provided by ALMA for upgrade and integration by NOVA.

First cryostat for LLAMA, produced by NAOJ.

NAsmyth Cabin Optical System (NACOS)

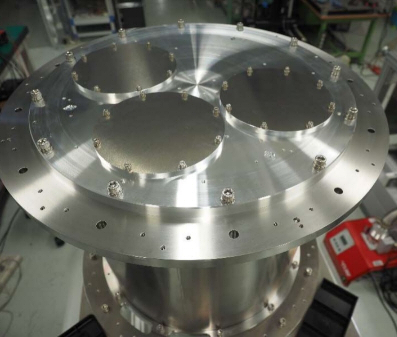

NACOS is a complex optoelectro-mechanical system designed to accommodate the set of mirrors that allows the incident light to be directed to the cabs at the Nasmyth focus and then to the receiver of interest. In addition, it has robotic arms to position the calibration loads. Considering that only cabin B will be used initially, NACOS bears and controls eight flat mirrors and two with curved surfaces, whose main requirement is to have a roughness of less than 0.5m.

Main mechanical parts of the NACOS structure after machining at the company ALFA Ferramentaria, in Araraquara (SP), under the supervision of Carlos Fermino. On the left, the CAssegrain Support Structure (CASS); right, NAsmyth Support Structure (NASS).